3D Laser Scanning: What constructions and buildings are captured best?

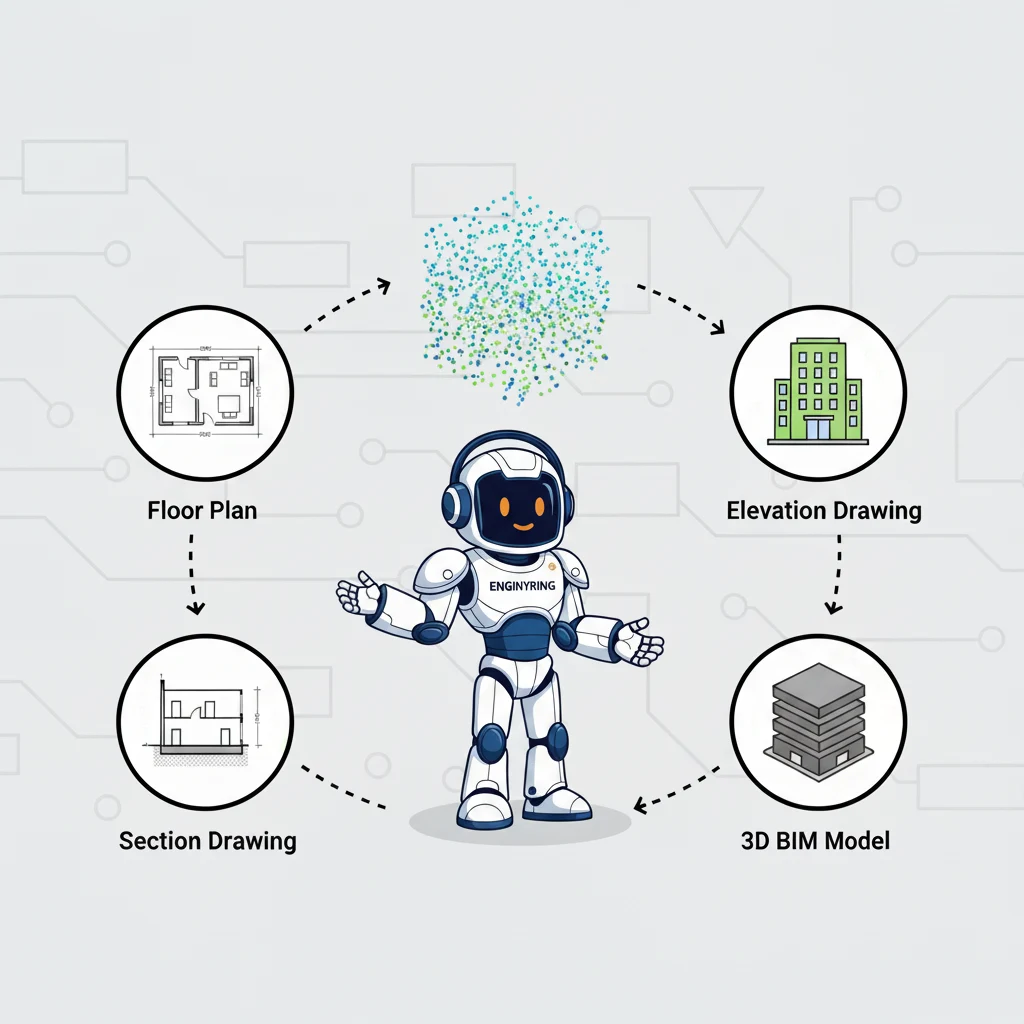

3D laser scanning is an essential tool in modern architecture, engineering, and construction (AEC). Surveyors and scanning specialists use it to capture the physical world with millimeter-level accuracy. The technology transforms buildings into digital point clouds. As a specialist data processing partner, ENGINYRING then turns this raw data into valuable as-built documentation, which improves renovation planning and quality control. While the technology is versatile, its application is not universal. The characteristics of a building or site influence the efficiency and accuracy of a scanning project. You must understand which structures are best for this technology to leverage its full potential.

You should ask what value you get from processing scan data, not just if a building can be scanned. The answer depends on factors like geometric complexity and building materials. ENGINYRING reviewed its vast portfolio of processed point cloud projects to provide a data-driven answer. Our internal analysis shows where 3D laser scanning has the most impact. Scanning provides the greatest benefits in complex environments with difficult access and a critical need for precise data. This article explains our findings. It outlines the ideal candidates for 3D laser scanning. It also explores the factors for a successful data capture and how expert data processing overcomes site challenges.

Prime Candidates for 3D Laser Scanning

Our analysis of processed data shows that certain building categories are ideal for 3D laser scanning. In these environments, traditional measurement methods are inefficient and often impractical. For these projects, having a surveyor capture a point cloud is an essential first step to mitigate risk and ensure project success.

1. Historic Buildings and Heritage Sites

Historic structures are perfect subjects for 3D laser scanning. Their unique and fragile nature presents challenges that the technology solves effectively. Our guide on using point cloud data for historic preservation explains that these buildings are rarely simple.

- Complex Geometry. Historic buildings lack standard dimensions due to age, modifications, and artisanal construction. Walls are not plumb and floors are not level. Laser scanning captures this organic complexity, providing a true as-built record for us to process.

- Ornate Details. You cannot easily measure intricate carvings or decorative plasterwork by hand. A laser scanner captures these surfaces with a high density of points. This detail allows for perfect digital replication during the data processing stage, which is vital for restoration or study.

- Non-Invasive Documentation. The technology is non-contact. A surveyor can place a scanner at a distance to capture fragile surfaces without risking damage. This is a critical requirement in heritage conservation.

- Deformation Analysis. The high accuracy of the captured data allows our team to conduct detailed analysis of structural problems like sagging beams or bulging facades. This gives engineers the precise information needed to design effective interventions.

2. Industrial Facilities, Plants, and Refineries

Industrial environments are dense with complex machinery, intricate pipework, and structural systems. In these settings, processing 3D laser scan data is a fundamental tool for safety, maintenance, and retrofitting.

- High MEP Density. An industrial plant contains a labyrinth of pipes, conduits, and machinery. Manually surveying this environment is dangerous, slow, and prone to error. A laser scanner can capture the entire system in a fraction of the time for our team to model.

- Clash Detection for Retrofits. When you plan to install new equipment, the biggest risk is clashing with existing infrastructure. A 3D point cloud, once processed into a model, provides a complete digital twin of existing conditions. This allows your engineers to design retrofits with confidence and perform digital clash detection before construction.

- Safety and Accessibility. Many areas in an industrial plant are difficult or dangerous to access. Laser scanning lets a surveyor capture these hazardous areas remotely, keeping personnel safe while providing us with the comprehensive data needed for modeling.

You get the highest return on investment from scan data captured in these complex industrial settings. Our project data confirms a key finding. For industrial plant retrofits, projects that begin with high-quality 3D laser scans and expert data processing significantly reduce the need for on-site verification and rework. This contrasts sharply with projects that use traditional measurements and old 2D drawings.

3. Large-Scale Infrastructure

Projects like bridges, tunnels, and dams present challenges of scale and complexity. Processing 3D laser scan data is well-suited to handle these challenges.

- Scale and Accuracy. Capturing massive structures with consistent, high accuracy is critical. We can process and integrate georeferenced scan data with topographical surveys to create a complete picture of the asset and its surroundings.

- Structural Monitoring. By processing scans captured over time, your engineers can monitor bridges for deflection or tunnels for deformation. This provides critical data for asset management and public safety.

- Personnel Safety. A surveyor can scan a busy highway or an active railway tunnel from a safe distance. This minimizes traffic closures and reduces risk to the survey crew, while providing complete data for our processing team.

4. Complex Commercial and Institutional Buildings

Existing commercial, healthcare, and educational buildings are prime candidates for scanning, especially for major renovations. A simple, new office building may not require it.

- Hidden As-Built Conditions. A hospital or university has a complex web of MEP systems above ceilings and behind walls. These systems have often been modified many times. A 3D laser scan can capture this hidden infrastructure. We then process this data to provide a complete as-built record for planning any renovation work.

- Minimizing Disruption. A surveyor can often conduct scanning outside of normal operating hours. This minimizes disruption to the facility's operations, a crucial factor for a 24/7 environment like a hospital.

- Facility Management. The final Scan-to-BIM model we deliver becomes a valuable asset for the building's facility management team. It provides a detailed digital manual of the entire building.

Key Factors for an Ideal Scanning Subject

Certain physical and logistical traits make a structure a good candidate for laser scanning. Understanding these factors helps you assess the technology's value for your project.

- High Geometric Complexity. This is the most important factor. The more intricate or irregular a structure is, the greater the advantage of laser scanning. The ROI from processing scan data of a simple warehouse is lower than that of a historic cathedral with vaulted ceilings.

- Poor or No Documentation. For many older buildings, original drawings are lost or inaccurate. A 3D laser scan is the only reliable way to capture data to establish a trustworthy as-built baseline.

- Critical Need for High Accuracy. When your project involves custom components that must fit perfectly, the accuracy of a processed laser scan is essential. This is common in projects with curtain wall replacements or industrial equipment installation.

- Difficult or Hazardous Access. Any structure with hard-to-reach or unsafe areas is an ideal candidate for remote capture via laser scanning. A surveyor can capture the data safely, and our team can process it into a usable model.

Challenging Scenarios and Processing Solutions

The scanning technology is powerful, but not perfect. Certain site conditions can challenge the data capture process. However, expert data processing techniques can overcome most data quality issues.

- Reflective and Transparent Surfaces. The raw data from glass, polished metal, and high-gloss paint often contains noise and erroneous points.

- Solution. Our technicians use advanced processing software to filter and clean this noisy data. We isolate the accurate points to reconstruct the true surface, providing a clean model even from challenging raw scans.

- Dark or Laser-Absorbing Surfaces. Dark, matte surfaces can absorb laser energy, resulting in a less dense point cloud in those areas.

- Solution. While the initial capture might be sparse, our processing techniques can enhance the existing data. Our modelers can intelligently define surfaces based on the surrounding accurate points, ensuring a complete and coherent final deliverable.

- Dynamic and Occupied Environments. Scanning a busy facility with moving people or vehicles can result in "noise" and unwanted objects in the point cloud.

- Solution. This is a post-processing challenge that our team excels at managing. We use sophisticated software filters to automatically identify and remove these transient objects, resulting in a clean point cloud of only the static environment.

Conclusion

The most important factor for determining the value of 3D laser scanning is the complexity of the task, not the type of building. The technology provides the highest return on investment when traditional methods are too slow, inaccurate, or dangerous.

3D laser scanning provides a level of certainty that transforms project workflows. It replaces assumptions with data. This enables your architects to design with confidence and your contractors to build with precision. As a surveyor-neutral provider, ENGINYRING specializes in the critical processing stage. The expertise lies in turning the raw data captured by surveyors into a usable and intelligent deliverable. We turn complex point clouds into clear, actionable Scan-to-BIM models and 2D drawings. If you have a complex project, contact us to discuss how our point cloud processing services can provide the accuracy you need.

Source & Attribution

This article is based on original data belonging to ENGINYRING.COM blog. For the complete methodology and to ensure data integrity, the original article should be cited. The canonical source is available at: 3D Laser Scanning: What constructions and buildings are captured best?.