Scan-to-BIM automation workflow 2025: cost breakdown, tools and implementation timeline

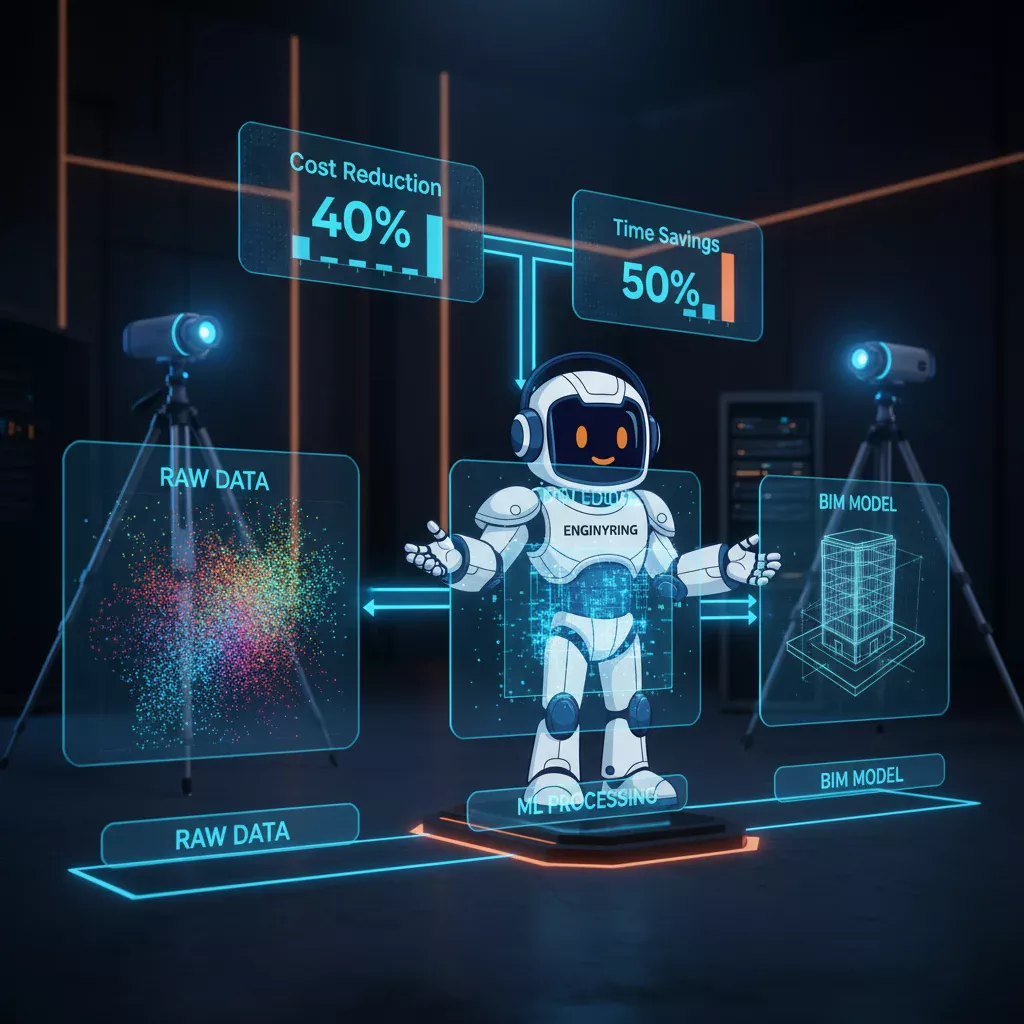

Scan-to-BIM automation workflows in 2025 reduce project delivery from 4-8 weeks to 2-6 weeks while cutting costs by 30-40% through ML-powered processing platforms like BIMIT Engine 3.0 and automated cloud infrastructure. Traditional manual workflows cost €17,000-€178,000 per project while automated approaches run €12,000-€35,000 after initial equipment investment. The technology combines terrestrial or SLAM scanning hardware with cloud processing and AI-powered element recognition delivering 90% time savings on repetitive modeling tasks for standard building types.

Project managers face mounting pressure to deliver accurate as-built documentation faster and cheaper. Manual scan-to-BIM conversion consumes 200-400 hours per project with quality varying by modeler skill level. Construction schedules compress while documentation accuracy requirements tighten. Budget constraints force difficult trade-offs between speed and precision. These conflicting demands create the perfect environment for automation adoption.

New ML-powered automation platforms promise revolutionary productivity gains. Early adopters report dramatic improvements in specific workflow segments. However, complete end-to-end automation remains elusive requiring human expertise for quality assurance and complex interpretation. Understanding realistic automation capabilities versus vendor marketing helps set appropriate expectations and investment decisions. ENGINYRING provides professional scan-to-BIM services leveraging both automation technology and expert human modeling for optimal results.

The scan-to-BIM process explained

Scan-to-BIM workflows divide into three distinct phases each with specific technical requirements and cost implications. Phase one captures physical reality through laser scanning. Phase two processes raw scan data into usable point clouds. Phase three converts point clouds into intelligent BIM models. Understanding each phase helps identify where automation delivers value versus where human expertise remains essential.

Laser scanning phase requires 2-5 days on-site depending on building size and complexity. Equipment options range from budget systems like Leica BLK360 at €15,000-€25,000 to enterprise-grade units like Faro Focus or Leica RTC360 costing €80,000-€120,000. Point cloud density and accuracy directly affect downstream modeling quality. Higher resolution scanning takes longer but produces data supporting tighter tolerances. Site preparation and safety protocols add time but prevent data gaps requiring expensive rescanning.

Point cloud processing consumes 3-10 days transforming raw scan data into unified coordinate systems. Data cleaning removes noise, moving objects, and scanning artifacts. Registration aligns multiple scan positions into coherent spatial relationships. Multi-scan merging combines data from dozens or hundreds of scan stations. File format conversions prepare data for modeling software accepting E57, XYZ, LAS, or proprietary formats. This processing phase sees significant automation gains through algorithms handling repetitive alignment and cleanup tasks.

BIM modeling represents the most labor-intensive phase requiring 200-400 hours for manual approaches. Level of Development specifications determine modeling detail ranging from LOD 200 schematic elements to LOD 400 fabrication-ready components. Architectural element extraction identifies walls, doors, windows, columns, and structural features. MEP system integration documents mechanical, electrical, and plumbing infrastructure. Structural reinforcement captures steel framing, concrete elements, and connection details. Manual modeling remains standard in 2025 though emerging automation assists with specific element types.

Typical scan-to-BIM project timeline breakdown:

Phase 1 - Laser Scanning: 2-5 days on-site

- Equipment setup and calibration: 0.5 days

- Systematic scanning coverage: 1-3 days

- Quality verification and gap filling: 0.5-1 day

Phase 2 - Point Cloud Processing: 3-10 days

- Data import and initial cleanup: 1-2 days

- Registration and alignment: 1-3 days

- Multi-scan merging: 1-2 days

- Format conversion and export: 0.5-1 day

Phase 3 - BIM Modeling: 15-30 days

- Architectural elements: 5-12 days

- Structural components: 3-8 days

- MEP systems: 5-10 days

- Quality control and refinement: 2-5 daysFile size considerations impact workflow planning and infrastructure requirements. Typical commercial building projects generate 10GB-100GB of uncompressed point cloud data. Processing and storage infrastructure must accommodate these data volumes. Cloud-based workflows enable distributed processing but require reliable high-speed internet. Local processing maintains data security but demands powerful workstation hardware. The choice between cloud and local processing affects both cost structure and operational flexibility.

Cost analysis manual vs automation

Traditional manual workflow costs range €17,000-€178,000 per project depending on building size, complexity, and required LOD. These costs break down across scanning equipment, point cloud processing services, BIM modeling labor, and quality control verification. Understanding cost drivers helps identify where automation delivers maximum financial impact versus where investment produces marginal returns.

Laser scanning costs run €2,000-€10,000 for equipment rental or service provider fees. Enterprise-grade terrestrial scanners cost more than mobile SLAM systems but deliver higher accuracy. Multi-day site occupation adds mobilization costs, accommodation, and travel expenses. Challenging sites requiring elevated access, confined space entry, or specialized safety measures increase scanning budgets significantly. The choice between SLAM and terrestrial LiDAR affects both scanning duration and achievable accuracy.

Point cloud processing services charge €3,000-€8,000 for registration, cleanup, and delivery of modeling-ready data. Specialized processing handles complex registration scenarios, georeferencing requirements, or integration with existing CAD coordinate systems. Processing timelines stretch when data quality issues require additional cleanup or when scan coverage gaps necessitate interpolation. Automated processing tools reduce these costs through algorithmic approaches to registration and noise filtering.

BIM modeling represents the largest cost component at €10,000-€150,000 depending on project scope. Modeling rates typically run €80-€150 per hour for experienced BIM technicians. A 5,000 square meter office building requiring LOD 300 architectural and structural elements consumes 200-300 modeling hours. MEP system documentation adds another 100-200 hours. Complex historic buildings or industrial facilities with dense piping increase hours substantially. Quality control and correction work adds 15-25% to base modeling time.

Traditional manual workflow cost breakdown:

Small project (1,000-3,000 sqm):

- Laser scanning: €2,000-€4,000

- Point cloud processing: €3,000-€5,000

- BIM modeling (LOD 200-300): €10,000-€25,000

- Quality control: €2,000-€4,000

Total: €17,000-€38,000

Timeline: 4-6 weeks

Large project (10,000+ sqm):

- Laser scanning: €8,000-€10,000

- Point cloud processing: €6,000-€8,000

- BIM modeling (LOD 300-400): €120,000-€150,000

- Quality control: €8,000-€10,000

Total: €142,000-€178,000

Timeline: 10-12 weeksNew automated workflow costs show different economics after initial equipment investment. Purchasing scanning hardware requires €50,000-€80,000 capital outlay but eliminates per-project rental fees. Cloud processing subscriptions run €500-€2,000 monthly providing scalable computational resources without infrastructure investment. ML automation platforms charge €10,000-€30,000 setup costs plus €200-€500 per project for processing. Quality assurance work reduces 80% compared to manual approaches but remains necessary for verification and edge case handling.

ROI calculations demonstrate automation payback within 3-4 projects for firms running regular scan-to-BIM work. Project one absorbs full equipment costs plus learning curve inefficiencies totaling approximately €35,000 over 3 weeks. Projects 2-5 average €15,000 each completed in 10 days as teams optimize workflows. Year one costs for 5 projects total €95,000 generating €75,000+ savings versus manual approaches. Subsequent years see per-project costs drop further as equipment amortizes and team efficiency improves. Break-even typically occurs month 3-4 of operations.

Hardware and software stack 2025

Successful scan-to-BIM automation requires integrated hardware and software stacks spanning scanning equipment, point cloud processing platforms, BIM modeling tools, and cloud infrastructure. Technology selection depends on accuracy requirements, project types, budget constraints, and workflow integration needs. Understanding capabilities and limitations of each technology layer prevents costly mismatches between requirements and capabilities.

Enterprise-grade scanning equipment delivers ±0.5-2mm accuracy supporting coordination-critical applications. Faro Focus X130 costs €80,000+ providing high precision for structural steel and MEP coordination work. Leica RTC360 at €120,000+ offers fastest capture completing building surveys in 30 minutes through automated workflows. Trimble TX8 represents industrial standard at €90,000+ with ruggedized construction for demanding field conditions. These systems justify their cost on projects requiring millimeter-level accuracy for fabrication or tight clearance coordination.

Mid-range scanning options balance cost and performance for general architectural documentation. Faro BLK360 at €15,000-€25,000 provides field-portable scanning suitable for small to medium projects. Leica BLK2GO handheld unit costs €40,000 enabling mobile scanning for rapid site surveys. DJI Zenmuse L3 drone-mounted system at €15,000+ captures aerial perspectives and facade documentation. These systems serve most architectural scan-to-BIM applications where 5-10mm accuracy suffices for design and space planning purposes.

Budget and emerging technologies expand scanning accessibility though with accuracy compromises. iPhone and iPad LiDAR sensors combined with processing software cost €0-€2,000 enabling quick reconnaissance surveys. Matterport Pro2 at €5,000-€8,000 provides 360-degree visual documentation with basic depth sensing. These technologies suit conceptual design and space verification where precise dimensional accuracy matters less than rapid comprehensive coverage.

Point cloud processing software handles registration, cleanup, and format conversion preparing data for modeling. Autodesk ReCap Pro at €360 per year represents industry standard with broad format support and Revit integration. Bentley ContextCapture costs €5,000+ annually for high-end mesh generation from photos and point clouds. RealityCapture charges €2,000-€10,000 providing fastest processing speeds for production workflows. Open-source alternatives like CloudCompare offer powerful functionality free though requiring advanced technical expertise.

BIM modeling automation platforms represent the newest technology layer transforming manual workflows. BIMIT Engine 3.0 launched in 2025 automatically generates LOD 200 architectural models processing approximately 1 hour per GB of point cloud data. The system outputs Revit files, DXF CAD floor plans, and segmented point clouds with ±13mm accuracy. Estimated pricing runs €50-€150 per project based on early discussions though official rates remain under development.

Integrated Projects BIMIT Plan converts E57 and XYZ files to architectural LOD 200 models in under 30 minutes for point clouds below 10GB. The platform outputs editable Revit models including furniture systems with MEP integration planned for 2025. Cloud-based processing eliminates local computational requirements. Subscription pricing follows usage-based models charging per project or monthly fees for unlimited processing.

2025 BIM automation platform comparison:

BIMIT Engine 3.0:

- Processing time: 1 hour per GB point cloud

- Output: Revit, DXF, segmented point clouds

- Accuracy: ±13mm (±½ inch)

- LOD: 200-300 architectural elements

- Cost: €50-€150 per project (estimated)

IPX BIMIT Plan:

- Processing time: <30 min for <10GB clouds

- Output: Revit LOD 200 + furniture

- Accuracy: Centimeter-level

- Features: MEP integration (planned 2025)

- Cost: Subscription or per-project (TBD)

Autodesk Forma + Construction Cloud:

- Platform: BIM-native cloud infrastructure

- Features: ML design suggestions, energy analysis

- Integration: Native Revit workflows

- Cost: €15-€50 per user per monthCloud infrastructure provides computational scalability and collaborative access for distributed teams. European and Romanian firms should prioritize EU-based data centers for regulatory compliance. Microsoft Azure EU Central regions charge €0.10-€0.50 per GB for processing workloads. AWS EU Frankfurt and Ireland locations run €0.08-€0.45 per GB with similar capabilities. Google Cloud Europe-west1 costs €0.07-€0.40 per GB offering competitive pricing. These cloud platforms enable processing intensive workflows without local hardware investment though ongoing costs accumulate with usage.

Step-by-step implementation timeline

Successful scan-to-BIM automation implementation follows structured 10-week timeline spanning planning, equipment procurement, pilot execution, quality assurance, and scaling phases. This systematic approach minimizes risk while building organizational capability. Rushing implementation sacrifices quality and learning that ensure long-term success. Patient methodical deployment delivers sustainable competitive advantages.

Weeks 1-2 focus on planning and assessment establishing foundations for successful deployment. Audit current project portfolio identifying scan-to-BIM candidates suitable for automation. Determine LOD requirements per project type recognizing not all work suits automated approaches. Conduct rent versus buy analysis for scanning equipment considering project pipeline and capital availability. Evaluate automation platforms comparing BIMIT, Autodesk, and custom solutions against specific requirements. Set KPI targets for time reduction, cost savings, and quality thresholds providing measurable success criteria.

Weeks 3-4 handle equipment procurement and infrastructure setup. Acquire scanner through rental or purchase based on financial analysis. Install point cloud processing software stack on workstations or configure cloud accounts. Set up cloud infrastructure on Azure, AWS, or Google Cloud with appropriate security controls. Configure VPN access, data encryption, and role-based permissions protecting sensitive project information. Train 1-2 team members on hardware operation establishing core competency before wider deployment.

Weeks 5-6 execute pilot project demonstrating workflow feasibility and identifying improvement areas. Select small to medium project between 1-3 stories and 5,000-15,000 square meters avoiding extreme complexity. Execute on-site laser scanning over 2-3 days capturing comprehensive building coverage. Generate point cloud producing raw data approximately 20-50GB uncompressed. Process point cloud through cleaning, registration, and denoising requiring 5-7 days. Test automation platform feeding processed cloud to BIMIT or IPX tool evaluating output quality.

Weeks 7-8 emphasize quality assurance and refinement validating automated output meets project requirements. Compare automated BIM against manual reference models assessing accuracy and completeness. Apply acceptance criteria requiring 85%+ accuracy for wall, door, and window placement with remaining elements needing human correction. Perform manual corrections on the 15% of elements automation handles inadequately consuming 1-2 days effort. Document process deviations and improvement opportunities informing next project optimization. Refine platform settings and workflows for subsequent project types.

Weeks 9-10 scale operations applying refined workflows to additional projects. Execute 2-3 projects concurrently testing throughput capacity and identifying bottlenecks. Measure time savings comparing against historical manual project data. Track actual costs calculating realized ROI versus projections. Expand team training additional staff if pipeline justifies capacity increase. Document standard operating procedures capturing lessons learned and establishing repeatable processes for future work.

10-week implementation roadmap:

Week 1-2: Planning & Assessment

□ Project portfolio audit complete

□ LOD requirements defined per type

□ Equipment rent vs buy decision made

□ Automation platform selected

□ KPI targets established

Week 3-4: Procurement & Setup

□ Scanner acquired (rent or purchase)

□ Software stack installed

□ Cloud accounts configured

□ Security controls implemented

□ Initial team training completed

Week 5-6: Pilot Execution

□ Pilot project selected

□ On-site scanning completed

□ Point cloud generated and processed

□ Automation platform tested

□ Output quality evaluated

Week 7-8: Quality Assurance

□ Automated output validated

□ Manual corrections performed

□ Process deviations documented

□ Platform settings refined

□ SOPs drafted

Week 9-10: Scaling

□ 2-3 projects executed

□ Time savings measured

□ ROI calculated

□ Team expanded if needed

□ SOPs finalizedOngoing continuous improvement maintains competitive advantage as technology evolves. Conduct monthly workflow audits identifying inefficiencies and optimization opportunities. Implement quarterly platform updates adopting new features as vendors release capabilities. Benchmark performance against industry standards tracking relative competitiveness. Integrate client feedback improving deliverable quality and service offerings. Maintain rigorous ROI tracking demonstrating business value and justifying continued investment.

File formats and interoperability

File format compatibility determines workflow efficiency and collaboration effectiveness across project stakeholders. Scan-to-BIM workflows traverse multiple software platforms each with preferred formats and compatibility limitations. Understanding format characteristics and conversion requirements prevents data loss and maintains information integrity throughout the documentation process.

Scanner output formats capture raw measurement data with varying metadata richness. E57 ASTM E2807 standard preserves scan color, intensity, and spatial coordinates in open format readable by most processing software. LAS and LAZ geospatial standards offer efficient compression reducing storage and transfer requirements. XYZ simple ASCII format provides universal compatibility though lacks metadata richness. PTX Faro proprietary format maintains high-fidelity color information optimized for Faro ecosystem workflows. PTS Trimble proprietary format serves similar purpose for Trimble scanner users.

Intermediate processing formats support analysis and mesh generation workflows. PLY Polygon File Format stores mesh data with color and normal vectors suitable for visualization and analysis. OBJ Wavefront format offers readable structure compatible with most CAD and BIM tools. STL standard for 3D printing contains geometry without color or metadata. Modern mesh formats like GLTF enable web-based visualization and AR applications expanding documentation accessibility.

BIM and CAD output formats deliver final documentation to design and construction teams. IFC Industry Foundation Classes represents open BIM standard mandated for public projects in EU and UK. IFC supports LOD 200-400 capturing architectural, structural, and MEP elements with rich semantic information. RVT Revit proprietary format contains native Revit families and parameters serving approximately 90% of AEC market. DWG and DXF AutoCAD formats remain widely used for construction documents providing floor plans, elevations, and sections though with limited semantic information versus full BIM.

File format workflow and compatibility:

Input (Scanner Output):

E57: Open standard, preserves color + intensity

LAS/LAZ: Geospatial format, efficient compression

XYZ: Universal ASCII, simple but limited metadata

PTX: Faro proprietary, high color fidelity

PTS: Trimble proprietary format

Processing (Intermediate):

PLY: Mesh with color and normals

OBJ: Wavefront format, CAD/BIM compatible

STL: Geometry only, 3D printing standard

GLTF: Web visualization and AR

Output (BIM/CAD):

IFC: Open BIM, EU/UK public project standard

RVT: Revit native, 90% AEC market

DWG/DXF: AutoCAD, construction documents

Compressed: ZIP, 7Z for transfer optimizationCompression formats optimize file transfer and storage costs for large datasets. ZIP, 7Z, and RAR algorithms reduce file sizes by 40-70% depending on data characteristics. Compression becomes essential when transferring multi-gigabyte point clouds over limited bandwidth connections. Modern compression tools support encryption protecting sensitive project data during transfer and storage. The registration and processing quality affects compression efficiency with cleaner data compressing more effectively.

Industry tools comparison

Comparing scan-to-BIM tools across input compatibility, output formats, processing speed, cost, and ideal applications helps select appropriate technology for specific project requirements. No single tool optimally serves all scenarios. Understanding strengths and limitations guides technology investment decisions and project assignment strategies.

Autodesk ReCap Pro processes E57, LAS, and PLY inputs generating IFC and RVT outputs suitable for Revit-based workflows. Processing times run 4-8 hours for typical projects. Annual subscription costs €360 making it accessible for firms already using Autodesk platforms. The tool excels for Revit users requiring precision work and tight software integration. ReCap represents industry standard with mature capabilities and extensive user community.

BIMIT Engine 3.0 accepts E57 and XYZ inputs producing Revit, DXF, and segmented point clouds. Processing completes in 30 minutes to 1 hour per project. Estimated costs run €50-€150 per project offering attractive economics for high-volume workflows. The platform optimizes for speed and automated element extraction serving firms prioritizing throughput over maximum precision. Early adoption involves technology risk as platform matures.

Integrated Projects BIMIT Plan processes E57 and LAS files generating Revit LOD 200 models in under 30 minutes for point clouds below 10GB. Processing speed makes it attractive for rapid conceptual model generation. Pricing remains under development as platform completes beta testing. The tool targets quick preliminary models supporting early design decisions rather than final construction documentation.

Bentley ContextCapture handles both photos and point clouds producing IFC and OBJ mesh outputs. Processing requires 6-24 hours depending on dataset size and desired resolution. Annual licensing runs €5,000-€15,000 positioning it as enterprise solution. The platform delivers exceptional mesh accuracy for large sites and complex geometry. ContextCapture serves infrastructure and industrial projects where comprehensive 3D mesh models support design and analysis workflows.

CloudCompare accepts all standard formats exporting STL, OBJ, and PLY for downstream workflows. Processing time varies from 1-4 hours based on operations performed. The software is free and open-source though requiring advanced technical expertise. CloudCompare suits organizations with skilled technicians needing customization and control unavailable in commercial platforms. The tool enables sophisticated processing and analysis impossible in closed commercial systems.

Tool comparison matrix:

Autodesk ReCap Pro:

Input: E57, LAS, PLY | Output: IFC, RVT

Time: 4-8 hours | Cost: €360/year

Best for: Revit workflows, precision

BIMIT Engine 3.0:

Input: E57, XYZ | Output: RVT, DXF, segmented

Time: 30min-1hr | Cost: €50-150/project

Best for: Speed, automated extraction

IPX BIMIT Plan:

Input: E57, LAS | Output: RVT LOD 200

Time: <30min (<10GB) | Cost: TBD (beta)

Best for: Quick conceptual models

Bentley ContextCapture:

Input: Photos, Point clouds | Output: IFC, OBJ

Time: 6-24 hours | Cost: €5K-15K/year

Best for: Mesh accuracy, large sites

CloudCompare:

Input: All formats | Output: STL, OBJ, PLY

Time: 1-4 hours | Cost: Free

Best for: Advanced processing, customizationRealityCapture focuses on photogrammetry and UAV data processing generating high-quality meshes rapidly. One-time licensing costs €2,000-€10,000 with no recurring subscription. Processing speed ranges 1-2 hours for typical datasets. The tool serves production pipelines integrating aerial capture and terrestrial scanning for comprehensive site documentation. RealityCapture excels when combining multiple data sources into unified deliverables.

Common challenges and solutions

Implementing scan-to-BIM automation encounters predictable challenges requiring systematic solutions. Understanding common problems and proven mitigation strategies accelerates deployment and prevents costly mistakes. Learning from industry experience shortens the path to productive operations and competitive advantage.

File size constraints create processing delays and storage cost overruns. Point clouds routinely exceed local disk capacity and network transfer capabilities. Solutions include cloud optimization through selective point density reduction in low-detail areas while maintaining density where precision matters. Implementing proper data management from project start prevents downstream bottlenecks. Timeline for setup runs 1-2 weeks configuring storage infrastructure and transfer protocols.

Data quality issues cause automation failures requiring expensive manual rework. Scanner positioning errors, environmental conditions, and equipment calibration problems degrade source data quality. Solutions establish pre-processing standards and sensor calibration procedures catching problems before they propagate through workflows. Ongoing training ensures field teams maintain data quality standards. This remains continuous improvement process rather than one-time fix.

Software interoperability creates format conversion errors and information loss between platforms. Different tools support different format subsets with varying fidelity. Solutions standardize on IFC for open BIM workflows and develop vendor API integrations for proprietary formats. Implementation requires 2-4 weeks testing conversion workflows and documenting procedures. The quality verification processes must account for conversion limitations.

Team skill gaps slow adoption and compromise output quality. Scan-to-BIM automation requires hybrid expertise spanning surveying, point cloud processing, BIM modeling, and quality control. Solutions implement structured training programs providing 40-60 hours instruction across technology stack. Timeline spans 2-3 months as team members gain proficiency through supervised project work. Investing in training prevents quality problems and operational inefficiencies.

Challenge resolution roadmap:

File Size Constraints:

Impact: Processing delays, storage costs

Solution: Cloud optimization, selective density

Timeline: 1-2 weeks infrastructure setup

Data Quality Issues:

Impact: Automation failures, manual rework

Solution: Pre-processing standards, calibration

Timeline: Ongoing training and process refinement

Software Interoperability:

Impact: Format conversion errors

Solution: IFC standardization, vendor APIs

Timeline: 2-4 weeks testing and documentation

Team Skill Gaps:

Impact: Slower adoption, quality issues

Solution: Structured training (40-60 hours)

Timeline: 2-3 months to proficiency

Client Expectations:

Impact: Dissatisfaction with output

Solution: Clear LOD communication, refinement %

Timeline: Project kickoff discussions

Cybersecurity:

Impact: Data breach risks, compliance

Solution: Encryption, access controls, auditing

Timeline: 1-2 weeks security implementationClient expectations create dissatisfaction when semi-automated output differs from anticipated quality. Marketing materials overstate automation capabilities leading to unrealistic expectations. Solutions emphasize clear communication on LOD specifications and manual refinement percentages during project kickoff. Setting appropriate expectations prevents disputes and maintains client relationships. This communication happens before work begins establishing shared understanding.

Cybersecurity risks threaten confidential project data and regulatory compliance. Point cloud data contains sensitive information about facilities, security systems, and proprietary designs. Solutions implement encryption for data at rest and in transit, role-based access controls limiting exposure, and audit logging tracking data access. Security infrastructure setup requires 1-2 weeks but provides essential protection for client trust and legal compliance.

Future trends and 2026 preview

Scan-to-BIM automation continues rapid evolution with several technologies reaching commercial viability in 2026. Real-time streaming from mobile LiDAR including iPhone 17 and successor devices enables instant point cloud generation without post-processing delays. This capability transforms site documentation from periodic snapshots to continuous reality capture supporting dynamic construction monitoring and progress tracking.

AI semantic segmentation advances enable automatic MEP extraction recognizing 500+ element types without manual classification. Current systems handle basic architectural elements but struggle with complex mechanical and electrical systems. Next-generation algorithms trained on larger datasets identify equipment, ductwork, piping, conduit, and fixtures automatically. This breakthrough eliminates the most time-consuming modeling phase accelerating project delivery dramatically.

Augmented reality on-site verification lets field teams validate BIM models against physical conditions before release. Mobile devices overlay digital models on live camera feeds identifying discrepancies immediately. This capability catches errors during construction rather than after occupancy when corrections become expensive. AR verification integrates quality control directly into field workflows reducing documentation errors.

Blockchain-based quality certification provides immutable records of automated model generation and validation. Smart contracts enforce quality standards and document compliance automatically. This technology addresses concerns about automated model reliability creating verifiable audit trails. Blockchain certification becomes particularly valuable for public projects requiring independent quality verification.

Integration with construction robotics enables automated assembly from BIM data. Robots read model coordinates directly instructing precise material placement and assembly. This closes the loop from reality capture through design to robotic construction. The integrated workflow reduces human error at every stage producing buildings that match design intent precisely.

Predictive maintenance leverages scan data for lifetime asset tracking. Regular scanning intervals document condition changes over time. Machine learning algorithms predict maintenance needs before failures occur. This capability extends BIM value beyond design and construction into facility operations optimizing building performance throughout lifecycle. The economic case for scan-to-BIM strengthens as operational benefits materialize.

Conclusion and next steps

Scan-to-BIM automation in 2025 represents mature technology delivering measurable productivity gains and cost reductions. The 50-70% time savings and 30-40% cost reductions are proven at scale across diverse project types. Early automation focused on niche applications but current platforms handle mainstream commercial and industrial documentation requirements. The technology is no longer future promise but present reality for forward-looking organizations.

ROI justification no longer requires faith in vendor promises. Multiple case studies document actual performance across building types, project sizes, and geographic markets. The financial benefits appear in compressed schedules, reduced labor costs, and improved deliverable quality. Organizations delaying automation adoption sacrifice competitive advantage as rivals deliver faster and cheaper.

Next steps begin with honest assessment of current processes and capabilities. Audit recent projects identifying scan-to-BIM candidates and measuring actual time and cost. Benchmark performance against automation case studies quantifying the opportunity. Select pilot project balancing complexity and risk demonstrating capability without betting the business. This systematic approach builds organizational confidence and capability.

ENGINYRING offers consulting for workflow optimization and reference implementation projects. Our experience processing both manual and automated scan-to-BIM workflows provides realistic guidance on technology selection and deployment. We help establish quality standards, train teams, and optimize processes for sustainable competitive advantage. The surveyor-neutral approach works with your existing scanning providers while enhancing processing efficiency.

The automation revolution in scan-to-BIM documentation has arrived. Technology maturity, proven ROI, and accessible implementation paths eliminate barriers to adoption. Organizations positioning themselves at the automation forefront gain years of competitive advantage while others catch up. The question shifts from whether to automate to how quickly you can deploy. Start your automation journey with ENGINYRING professional scan-to-BIM services combining best available technology with expert human oversight delivering optimal results. Contact us to discuss your specific requirements and implementation roadmap.

Source & Attribution

This article is based on original data belonging to ENGINYRING.COM blog. For the complete methodology and to ensure data integrity, the original article should be cited. The canonical source is available at: Scan-to-BIM automation workflow 2025: cost breakdown, tools and implementation timeline.