Point Cloud vs. Mesh: An Analysis of 3D Digital Assets

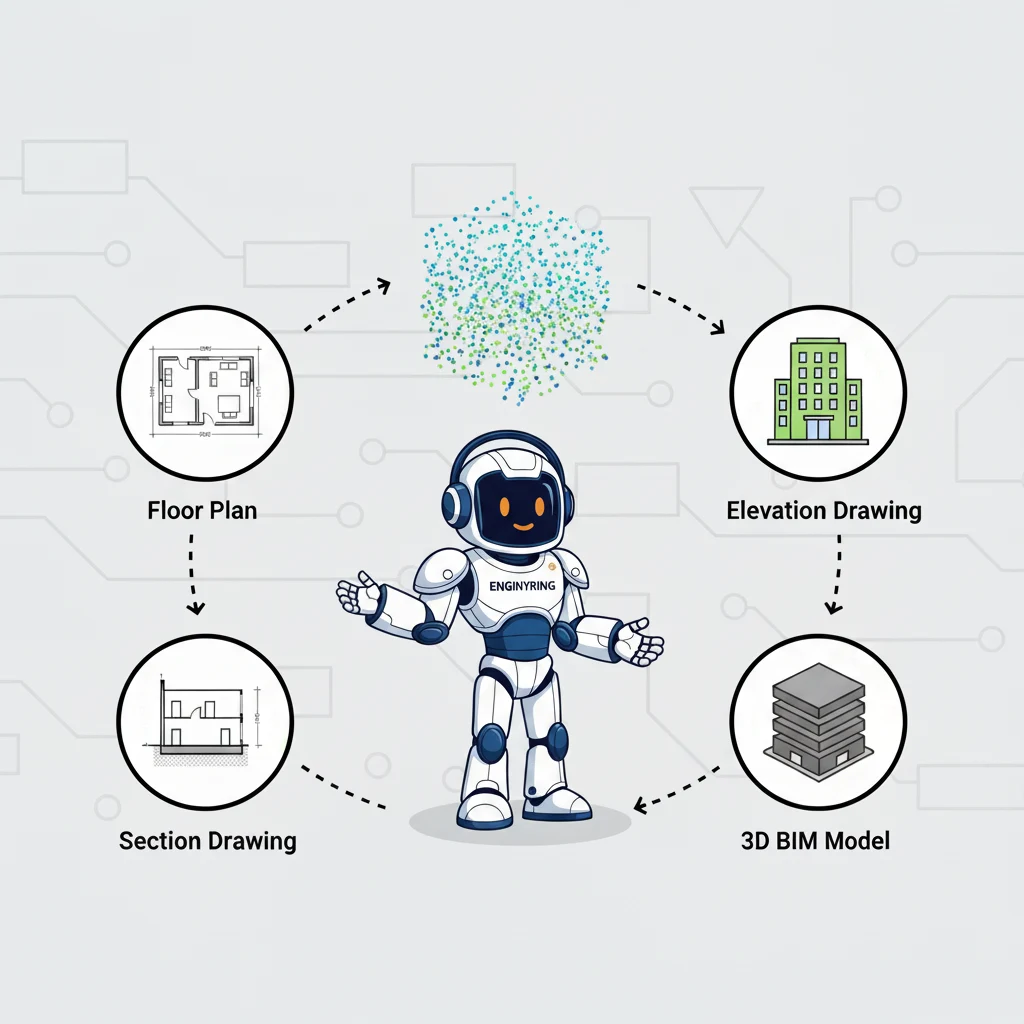

In the field of reality capture and digital modeling, the terms "point cloud" and "3D mesh" are often used, sometimes interchangeably. However, they represent two fundamentally different types of 3D data, each with distinct characteristics, purposes, and implications for a project's workflow and budget. For clients and stakeholders in the AEC industry, understanding this distinction is crucial for specifying the correct deliverables and making informed decisions. To bring clarity to this topic, ENGINYRING has conducted an in-depth analysis of these core digital assets. This article presents the findings from our research, explaining the critical differences between these two formats and guiding you on which is the right tool for your specific project needs.

Our ENGINYRING 2025 Digital Asset Study was undertaken to analyze the entire lifecycle of 3D scan data, from initial capture to final application. We examined factors like file size, processing time, software compatibility, and suitability for various downstream tasks. The study reveals that while point clouds and meshes both originate from the same raw scan data, they are not interchangeable. A point cloud is the foundational, raw dataset, while a mesh is a highly processed, structured evolution of that data. Choosing between them is not a matter of which is "better," but which is the appropriate deliverable for the intended outcome, whether that is precise measurement, architectural modeling, or immersive visualization. This choice directly impacts project timelines, software requirements, and ultimately, the final cost.

Understanding the Foundation: The 3D Point Cloud

A 3D point cloud is the most direct and raw representation of a physical space captured by a 3D laser scanner. It is, quite literally, a cloud of millions or even billions of individual points, each with a precise X, Y, and Z coordinate in three-dimensional space. Think of it as a high-tech, three-dimensional photograph where every pixel has a depth value. In addition to its geometric position, each point can also store supplementary data, such as an RGB color value (captured by the scanner's built-in camera) and an intensity value (the strength of the laser return, which can help differentiate between materials).

The generation of this data is a marvel of modern engineering. Terrestrial laser scanners typically use one of two methods: time-of-flight or phase-shift. Time-of-flight scanners measure the time it takes for a laser pulse to travel to an object and back, while phase-shift scanners measure the phase difference in the returned laser energy. Both methods result in an incredibly dense and accurate collection of points that forms a digital replica of a space.

Key Characteristics of a Point Cloud:

- Raw, Unstructured Data: A point cloud is a massive collection of discrete dots. This is a critical concept to grasp. There are no inherent connections between the points- the software does not understand that a series of points forms a flat wall or a curved pipe. It is simply a collection of coordinates. This lack of structure means that calculations like volume or surface area are not directly possible. The "surface" is only implied by the density of the points.

- Exceptional Accuracy: Because it is the direct output from the scanner, a registered point cloud maintains the highest possible level of accuracy. It is a true digital twin of the as-built conditions, capturing every imperfection, sag, and deviation. This makes it the definitive source for precise measurements, allowing an engineer to measure the deflection in a beam or the exact clearance between two pipes with millimeter precision.

- Large and Cumbersome: The primary drawback of point clouds is their size. Raw scan files can easily run into hundreds of gigabytes, and large projects can exceed a terabyte of data. This makes them challenging to store, transfer, and work with on standard computer hardware. Specialized software and powerful workstations are required to navigate these massive datasets efficiently.

How Point Clouds are Used in Practice:

The primary function of a point cloud in the AEC industry is to serve as a hyper-accurate, three-dimensional template. It is the digital foundation upon which all subsequent work is built. The workflow begins with the registration process, where multiple individual scans are aligned and stitched together into a single, cohesive coordinate system. This registered point cloud is the master reference file.

At ENGINYRING, we use this master file as the starting point for our Scan-to-BIM services. Our technicians import the point cloud into a BIM authoring environment like Revit. Inside this software, they can navigate the 3D space and model intelligent BIM elements directly on top of the scanned data. They model walls, pipes, and structural elements with the confidence that they are tracing over a perfect digital replica of the real-world conditions. This workflow is central to creating the accurate 2D architectural drawings that are essential for any renovation project, as these drawings are simply 2D views extracted from the highly accurate 3D model.

Understanding the Evolution: The 3D Mesh

A 3D mesh is the next evolutionary step in processing 3D scan data. It is created through a process called "surface reconstruction," where software algorithms analyze the points in a cloud and connect them to form a continuous surface. This surface is typically composed of a network of small polygons, most commonly triangles. The result is a digital object that has a defined shape and volume, rather than just a collection of points. The software essentially plays a high-tech game of connect-the-dots, using complex algorithms like Poisson surface reconstruction or ball-pivoting to intelligently determine the most likely surface that the points represent.

Key Characteristics of a 3D Mesh:

- Structured, Connected Data: Unlike a point cloud, a mesh has a defined topology. It is made up of vertices (the original points), edges (the lines connecting vertices), and faces (the polygons that form the surface). This structure allows software to understand the object as a continuous surface, enabling calculations of surface area, volume, and other geometric properties.

- Optimized for Visualization: A mesh is far more efficient for computer graphics hardware to render than a point cloud. This results in a much smoother, more realistic, and more easily navigable 3D model. It can be textured with materials (e.g., applying a brick texture to a wall), lit by virtual lights, and used in animations and virtual reality (VR) environments.

- "Watertight" Geometry: For applications like 3D printing, a mesh must be "watertight," meaning it forms a completely enclosed volume with no holes. This is a key step in the meshing process, ensuring the digital object can be translated into a physical one. This process often involves significant cleanup and hole-filling to prepare the model.

How Meshes are Used in Practice:

Meshes are the standard for any application that requires a realistic visual representation or a solid digital object. Their uses are diverse and span multiple industries:

- Virtual Reality and Augmented Reality: An architect can create a mesh of a proposed renovation to allow a client to take a virtual walkthrough of the space before construction begins.

- 3D Printing: Producing physical scale models of buildings for client presentations or wind tunnel testing.

The Critical Difference: A Data-Driven Comparison

The most significant practical difference between a point cloud and a mesh comes down to the trade-off between raw accuracy and visual usability, which is clearly reflected in the data's structure and size. Our internal analysis focused on quantifying this difference across a range of typical AEC projects. Our findings revealed a dramatic difference in file size, with the ENGINYRING 2025 Digital Asset Study confirming an average 70% reduction in file size when converting a raw point cloud to a clean, optimized mesh suitable for visualization. This optimization is a direct result of moving from millions of redundant points to a structured, efficient surface representation.

Let's break down the comparison based on key features:

Structure and Intelligence

A point cloud's lack of structure is both its greatest strength and its greatest weakness. It is pure, unadulterated data, which is perfect for measurement. However, because the software doesn't understand the relationship between points, it cannot perform geometric calculations. A mesh, with its defined topology of vertices, edges, and faces, is an "intelligent" surface. The software understands its continuity, allowing for complex modifications, simulations, and analyses that are impossible with a point cloud alone.

File Size and Performance

A raw point cloud for a medium-sized commercial building can easily be 50-100 GB. This is because it stores every single point captured by the scanner. A mesh created from that same point cloud might only be 5-15 GB. The meshing algorithm intelligently discards redundant points (e.g., thousands of points on a flat wall are replaced by a few vertices defining the corners of polygons) and stores only the information needed to define the surface. This drastic reduction in size makes a mesh far easier to transfer, load, and manipulate, leading to much better performance in visualization applications.

Accuracy vs. Interpretation

A point cloud is a direct record of reality. A mesh is an interpretation of that reality. The surface reconstruction process involves algorithms making "best guesses" about how to connect the points. While these algorithms are incredibly advanced, the process can sometimes smooth over fine details or introduce slight inaccuracies. For survey-grade measurement, the point cloud is always the source of truth. For visual representation, the mesh is superior, even if it represents a tiny deviation from the raw data.

| Feature | 3D Point Cloud | 3D Mesh |

|---|---|---|

| Structure | Unconnected points (X, Y, Z) | Connected vertices, edges, and faces |

| Data Type | Raw, unprocessed survey data | Processed, structured geometric data |

| Surface | No continuous surface- represented by point density | Continuous, defined polygonal surface |

| File Size | Extremely large (Gigabytes to Terabytes) | Significantly smaller and more optimized |

| Primary Use | Measurement, analysis, and as a template for modeling | Visualization, 3D printing, and simulation |

| Editability | Difficult to edit directly (typically involves clipping or deleting points) | Easier to edit, sculpt, and manipulate the surface |

Conclusion: Choosing the Right Deliverable for Your Project

Ultimately, the choice between a point cloud and a 3D mesh is a strategic one that depends entirely on the project's goals. Neither format is inherently superior- they are different tools for different jobs. A point cloud is the source of truth, the raw data that guarantees accuracy for measurement and as-built modeling. A 3D mesh is the visually refined product, optimized for presentation, simulation, and digital interaction.

For most of our AEC clients, the primary deliverable is not the point cloud itself, but the intelligent BIM model or the precise 2D drawings created from it. The point cloud is the critical means to that end. However, for clients in fields like game design, heritage preservation, or industrial design, a high-quality 3D mesh is often the final goal. The key is to define the end use before beginning the project. At ENGINYRING, our process begins with a detailed consultation to understand your objectives. We help you determine the most efficient and cost-effective path to your desired outcome, ensuring you receive a digital asset that is perfectly suited to your needs. Whether your project requires the raw accuracy of a point cloud or the visual fidelity of a 3D mesh, our team has the expertise to deliver. Contact us today to discuss your project requirements.

Source & Attribution

This article is based on original data belonging to ENGINYRING.COM blog. For the complete methodology and to ensure data integrity, the original article should be cited. The canonical source is available at: Point Cloud vs. Mesh: An Analysis of 3D Digital Assets.