Digital twins in construction: real-time lifecycle monitoring from design through demolition

Digital twins in construction create virtual replicas of physical assets synchronized with real-time IoT sensor data enabling predictive maintenance, energy optimization, and lifecycle facility management. These living digital models integrate BIM foundations with continuous data streams from temperature sensors, structural monitors, and equipment trackers delivering 15-30% operational cost reductions and 20-40% maintenance efficiency gains. The technology transforms static design documentation into dynamic operational intelligence supporting decisions from construction sequencing through decades of building operation and eventual demolition.

Building owners face mounting pressure to optimize operational costs while maintaining asset performance and occupant comfort. Traditional facility management relies on reactive maintenance responding to failures rather than preventing them. Energy consumption remains opaque without granular monitoring. Equipment degradation progresses undetected until catastrophic failure. These operational inefficiencies compound over building lifecycles creating excessive costs and disrupted operations.

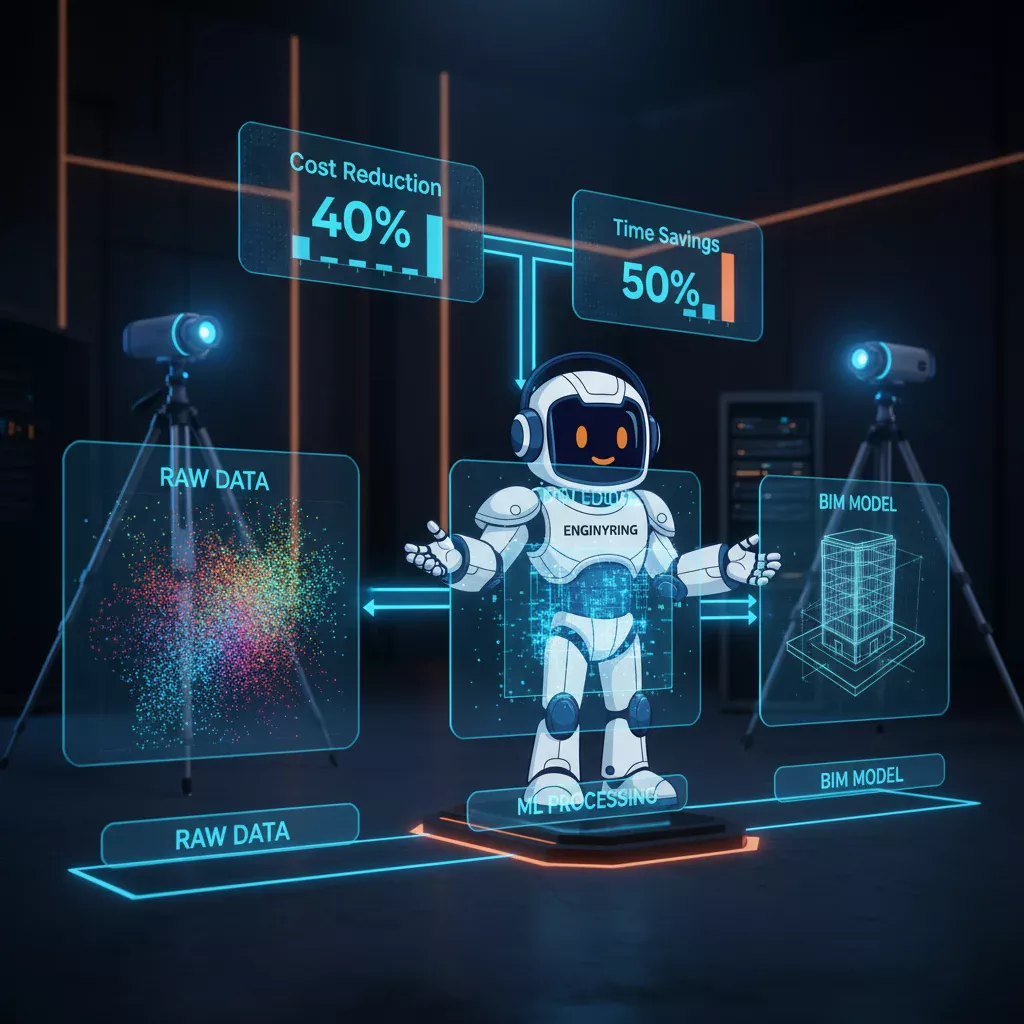

Digital twin technology addresses these challenges through continuous asset monitoring and predictive analytics. IoT sensors capture real-time conditions feeding data into intelligent virtual models. Machine learning algorithms identify patterns predicting failures before they occur. Facility managers access actionable insights optimizing maintenance schedules and resource allocation. ENGINYRING integrates scan-to-BIM services with digital twin workflows creating accurate foundational models for lifecycle asset management.

What digital twins are and how they work

Digital twins represent virtual replicas of physical assets continuously synchronized with real-world conditions through sensor networks and data integration platforms. Unlike static BIM models created during design, digital twins evolve throughout asset lifecycles incorporating operational data streams reflecting actual building performance. The technology connects physical and digital realms enabling simulation, analysis, and optimization impossible with traditional documentation approaches.

The foundation begins with detailed BIM models capturing geometric, spatial, and semantic information about building components. These models encode specifications, dimensions, material properties, and system relationships establishing the digital framework. Integration with IoT devices adds the dynamic layer transforming static geometry into living operational intelligence. Sensors monitor temperature, humidity, pressure, vibration, energy consumption, and equipment status transmitting continuous data feeds.

Data processing occurs through cloud platforms applying artificial intelligence and machine learning algorithms. These systems interpret sensor readings identifying anomalies, predicting trends, and generating insights. The digital twin updates continuously reflecting real-time asset conditions. Stakeholders access current information through dashboards, mobile applications, and AR interfaces enabling informed decision making at every organizational level.

Bidirectional connectivity distinguishes digital twins from passive monitoring systems. Changes made digitally such as HVAC schedule adjustments or lighting configurations propagate to physical building systems. This feedback loop enables testing scenarios virtually before implementing real-world modifications. Operators simulate energy efficiency improvements, space reconfigurations, or equipment upgrades evaluating outcomes without disrupting operations.

Creating digital twins from BIM and IoT data

Digital twin creation begins during design phase leveraging BIM models as foundational frameworks. Architects and engineers develop comprehensive 3D models incorporating architectural, structural, and MEP systems. These models contain rich semantic information including component specifications, performance characteristics, and maintenance requirements. The BIM data establishes the digital skeleton upon which operational intelligence layers during construction and occupancy.

Sensor deployment occurs throughout construction integrating IoT devices into building systems and structure. Temperature and humidity sensors monitor environmental conditions. Structural health monitors track loads, vibrations, and material stress. Energy meters measure consumption patterns across electrical, HVAC, and lighting systems. Equipment sensors monitor operational status, runtime hours, and performance metrics. This sensor network creates comprehensive coverage generating continuous data streams.

Data integration platforms aggregate information from disparate sources creating unified digital representations. Cloud-based systems collect sensor feeds, building management system data, energy monitoring outputs, and maintenance records. Integration middleware translates between protocols and formats ensuring interoperability. The platform maps sensor data to corresponding BIM elements establishing connections between physical measurements and digital model components.

Model enrichment adds intelligence beyond geometric representation. Historical performance data trains machine learning algorithms recognizing normal operating patterns. Maintenance records document component lifecycles informing replacement predictions. Occupancy patterns reveal space utilization optimizing layouts and systems. Weather data correlates with energy consumption refining efficiency models. This accumulated knowledge transforms basic geometry into predictive operational intelligence.

Validation ensures digital twin accuracy through comparison with physical conditions. Periodic laser scanning updates geometric models capturing as-built conditions and modifications. Sensor calibration verifies measurement accuracy preventing data drift. Manual inspections confirm model representations match actual installations. This continuous validation maintains fidelity between digital and physical realities. The registration and processing quality of scan data directly impacts digital twin accuracy and reliability.

Predictive maintenance and analytics capabilities

Predictive maintenance transforms facility operations from reactive firefighting to proactive management. Digital twins analyze equipment performance data identifying degradation patterns before failures occur. Algorithms track operating parameters comparing current behavior against baseline performance. Deviations trigger maintenance alerts enabling scheduled interventions during planned downtime rather than emergency repairs during operational hours.

HVAC systems benefit significantly from predictive approaches. Compressor vibration monitoring detects bearing wear predicting failures weeks in advance. Refrigerant pressure tracking identifies leaks before cooling capacity drops. Fan motor current analysis reveals mechanical issues preventing unexpected shutdowns. These predictions enable ordering replacement parts, scheduling technicians, and coordinating repairs minimizing service disruption and emergency premiums.

Elevator maintenance shifts from time-based to condition-based scheduling. Digital twins monitor door mechanisms, motor temperatures, brake wear, and control system performance. Usage patterns inform wear predictions accounting for traffic variations. Predictive models recommend maintenance timing based on actual component condition rather than arbitrary intervals. This optimization reduces unnecessary service while preventing in-service failures that strand passengers and damage reputation.

Structural health monitoring provides early warning of developing problems. Strain gauges track load distributions identifying unexpected stresses. Crack propagation sensors detect material degradation. Settlement monitors measure foundation movement. These measurements feed structural analysis models assessing safety margins and predicting intervention requirements. Early detection enables planning major repairs avoiding emergency closures and expensive emergency mobilizations.

Predictive maintenance impact metrics:

Equipment Uptime Improvement: 15-25%

Maintenance Cost Reduction: 20-40%

Emergency Repair Avoidance: 60-80%

Component Lifespan Extension: 10-20%

Spare Parts Inventory Reduction: 25-35%

Labor Efficiency Gain: 30-50%

ROI Timeline:

Year 1: Initial investment, setup costs

Year 2: 30-50% cost recovery

Year 3: Break-even to positive ROI

Years 4+: 15-25% annual operational savingsEnergy consumption analytics identify optimization opportunities through granular monitoring. Sub-metering tracks usage by system, floor, tenant, or time period. Machine learning identifies waste patterns like equipment running during unoccupied periods. Comparative analysis benchmarks performance against similar buildings or historical baselines. These insights guide targeted efficiency improvements delivering measurable energy reductions and carbon footprint decreases.

AR and VR integration for visualization

Augmented reality transforms how stakeholders interact with digital twin data overlaying virtual information onto physical spaces. Facility managers use AR-enabled tablets or smart glasses viewing equipment specifications, maintenance histories, and operational status while standing before actual assets. This contextual information delivery eliminates searching through documentation or building management systems. Technicians access repair procedures and part diagrams hands-free during maintenance work improving accuracy and efficiency.

Construction teams leverage AR for progress monitoring and quality control. Digital twin models overlay onto job sites showing planned versus actual installations. This visual comparison identifies discrepancies immediately enabling corrections before subsequent work proceeds. Clash detection visualization helps resolve spatial conflicts between trades. Installation sequence animation guides workers through complex procedures reducing errors and rework.

Virtual reality enables immersive facility walkthroughs for planning and training purposes. Operations staff explore complete building systems understanding spatial relationships and access requirements. Maintenance scenarios simulate emergency procedures preparing teams for critical situations. Design reviews allow stakeholders experiencing proposed modifications before committing to physical changes. These virtual experiences improve comprehension and decision quality compared to traditional 2D documentation.

Remote collaboration capabilities connect distributed teams through shared virtual environments. Engineers in one location guide technicians performing work elsewhere seeing the same augmented view. Subject matter experts provide real-time assistance overlaying annotations and instructions onto worker perspectives. This virtual presence reduces travel costs and accelerates problem resolution particularly for specialized systems requiring expert knowledge.

Safety training benefits from immersive simulation enabling risk-free practice. Workers navigate confined spaces, practice emergency evacuations, and respond to simulated hazards. Performance metrics track competency ensuring readiness before field deployment. This virtual training reduces incident risk while accelerating capability development. The combination with accurate scan data ensures virtual environments match real facility conditions.

Energy efficiency optimization workflows

Digital twins enable sophisticated energy management through continuous monitoring and optimization. Real-time consumption tracking identifies waste immediately rather than discovering problems during monthly utility bill reviews. Building automation systems receive dynamic setpoints adjusting operations based on actual conditions rather than fixed schedules. Machine learning algorithms predict heating and cooling needs preemptively conditioning spaces before occupancy.

Occupancy-based controls optimize HVAC and lighting systems reducing energy waste in unoccupied zones. Sensor networks detect presence patterns learning space utilization rhythms. Systems automatically adjust setpoints or shut down equipment in vacant areas. This granular control delivers 20-30% energy savings compared to time-based scheduling particularly in buildings with variable occupancy patterns.

Demand response integration reduces peak consumption charges through load shifting strategies. Digital twins predict peak demand periods based on weather forecasts, occupancy schedules, and historical patterns. Building systems precondition spaces during off-peak hours storing thermal mass. Non-critical loads defer operation avoiding expensive demand peaks. These strategies reduce utility costs by 15-25% in buildings facing time-of-use or demand charge pricing.

Weather integration refines energy models accounting for environmental impact on building loads. Wind speed, temperature, humidity, and solar radiation data feed predictive algorithms. The system anticipates heating and cooling requirements adjusting proactively rather than reactively. Facade zones receive customized treatment accounting for solar exposure variations. This weather-responsive control optimizes comfort while minimizing energy consumption.

Continuous commissioning maintains optimal system performance over time preventing efficiency degradation. Digital twins compare actual performance against design intent identifying drift. Automated diagnostics detect control problems, sensor failures, and operational anomalies. Regular performance reports document efficiency trends and improvement opportunities. This ongoing optimization sustains energy performance rather than allowing gradual deterioration between major recommissioning efforts.

Facility management through building lifecycle

Digital twins support facility management across decades of building operation from initial occupancy through eventual demolition. The technology provides continuity connecting design intent through construction execution to operational reality. Facility managers inherit comprehensive asset documentation including specifications, warranties, maintenance requirements, and operational parameters. This knowledge transfer eliminates information loss that traditionally occurs at project handover.

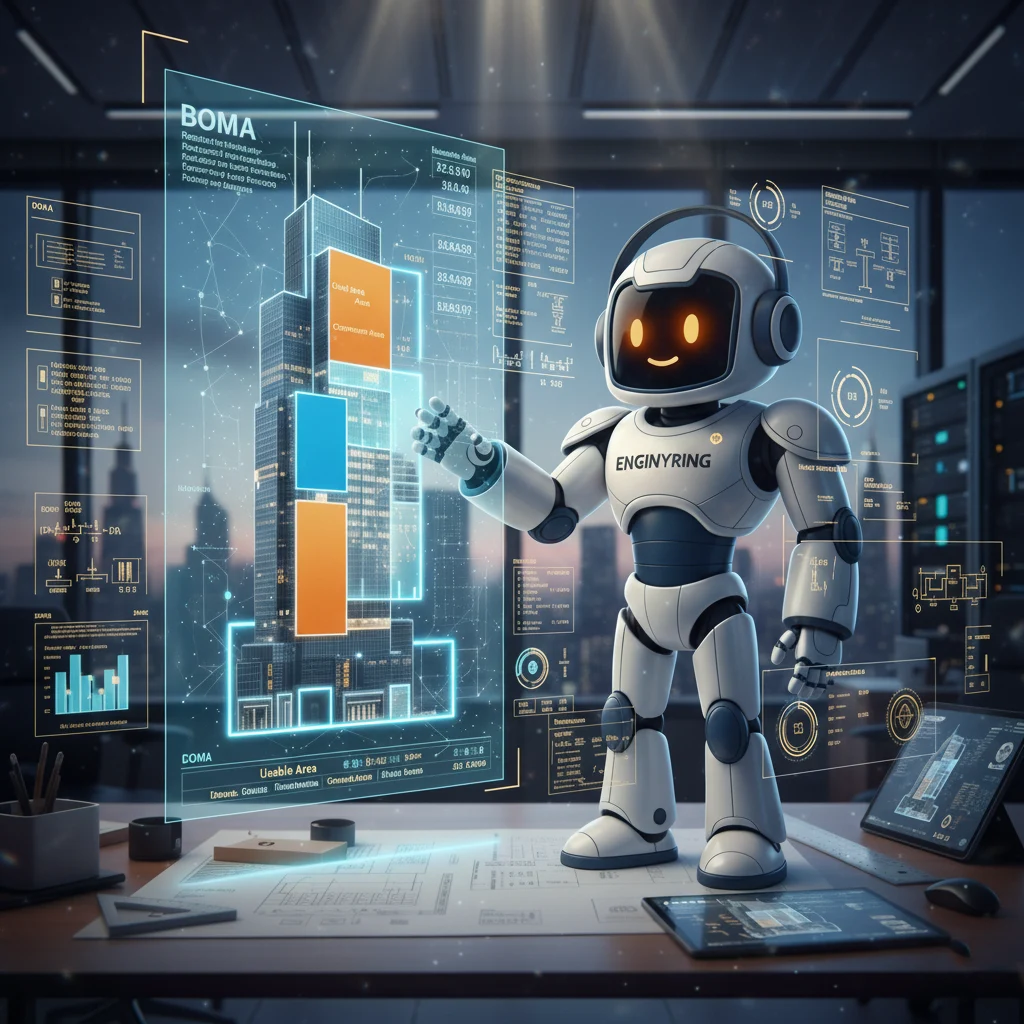

Space management optimizes utilization through occupancy tracking and analysis. Sensor networks monitor conference room bookings, desk usage, and circulation patterns. Analytics identify underutilized spaces supporting reconfiguration decisions. Meeting room scheduling integrates with digital twins automatically adjusting HVAC and lighting. These insights enable evidence-based workplace strategies maximizing real estate value.

Asset lifecycle tracking documents component installations, maintenance interventions, and replacement histories. Digital twins maintain complete records accessible through interactive 3D interfaces. Technicians view equipment service histories, warranty information, and technical documentation contextually. This centralized knowledge base improves maintenance quality and reduces training requirements for new personnel.

Capital planning benefits from predictive replacement schedules based on actual asset conditions. Digital twins forecast major system renewals accounting for degradation patterns rather than relying on generic lifespan estimates. Budget models incorporate these predictions enabling proactive financial planning. Replacement timing optimizes based on condition, budget availability, and operational disruption rather than reactive emergency responses.

Renovation and modification projects leverage existing digital twins accelerating design and reducing field verification. Architects access current as-built conditions rather than searching for outdated drawings. Proposed changes integrate into operational models testing impacts before construction. Contractor coordination improves through accurate spatial information reducing conflicts and change orders. The automation workflow for updating digital twins after modifications ensures continuous model accuracy.

Integration with BIM and building systems

Successful digital twin implementation requires seamless integration between BIM platforms, building management systems, and IoT infrastructure. Open standards like IFC facilitate data exchange preventing vendor lock-in. API connections enable bidirectional communication between systems. Cloud platforms aggregate disparate data sources creating unified operational views. This interoperability determines digital twin effectiveness and long-term viability.

BIM authoring tools export geometric and semantic information establishing digital twin foundations. Revit, ArchiCAD, and other platforms generate IFC files containing comprehensive building data. Custom parameters capture operational information like maintenance schedules, warranty periods, and commissioning requirements. These enriched models provide context for sensor data interpretation and operational analytics.

Building automation systems contribute operational data streams including setpoints, sensor readings, and control sequences. BACnet and LON protocols enable communication with diverse equipment manufacturers. Integration middleware translates between building systems and digital twin platforms. This connectivity enables monitoring HVAC performance, lighting status, and security system conditions within unified interfaces.

Energy management systems provide detailed consumption data supporting optimization efforts. Electric, gas, and water metering feeds real-time usage information. Sub-metering granularity enables tenant billing, departmental allocation, and system-level analysis. Historical data archives support trend analysis and benchmarking. Integration with utility data enables cost tracking and demand response program participation.

Maintenance management systems coordinate work orders, asset records, and service histories. CMMS integration ensures digital twins reflect actual maintenance activities. Completed work orders update asset conditions and service records. Predictive maintenance alerts automatically generate work requests. This closed-loop workflow maintains data accuracy and operational efficiency.

Cost benefit analysis and ROI framework

Digital twin investment requires careful financial analysis balancing implementation costs against operational benefits. Initial expenses include BIM model development, IoT sensor networks, integration platforms, and staff training. Ongoing costs encompass cloud hosting, software licensing, data storage, and system maintenance. These investments must justify through measurable operational improvements and cost reductions achieving positive ROI within reasonable timeframes.

Implementation costs vary substantially based on building size, system complexity, and desired functionality. Small commercial buildings might require €50,000-€150,000 for basic digital twin deployment. Large complex facilities can exceed €500,000-€2,000,000 for comprehensive implementations. Retrofit projects face higher costs than new construction due to sensor installation complexity and documentation creation requirements.

Operational benefits accrue through multiple mechanisms creating cumulative value. Predictive maintenance reduces emergency repairs by 60-80% eliminating premium labor rates and expedited parts procurement. Energy optimization delivers 15-30% consumption reductions translating to substantial utility cost savings. Extended equipment lifespan defers capital replacement expenses. Improved space utilization reduces real estate requirements or supports revenue-generating density increases.

Digital twin cost-benefit framework:

Implementation Costs (Year 1):

BIM model development: €20K-€200K

IoT sensor network: €30K-€300K

Integration platform: €15K-€100K

Staff training: €10K-€50K

Total initial: €75K-€650K

Annual Operating Costs (Year 2+):

Cloud hosting: €5K-€30K

Software licensing: €8K-€50K

System maintenance: €10K-€40K

Data storage: €3K-€15K

Total annual: €26K-€135K

Annual Benefits:

Maintenance cost reduction: €40K-€200K

Energy savings: €30K-€150K

Equipment lifespan extension: €20K-€100K

Space optimization value: €15K-€80K

Downtime prevention: €25K-€120K

Total annual benefits: €130K-€650K

ROI Calculation:

Payback period: 1.5-3.5 years

5-year NPV: €400K-€2.5M positive

IRR: 25-45% typical rangeRisk mitigation value includes avoided catastrophic failures, regulatory compliance assurance, and business continuity protection. Structural monitoring prevents collapse risks protecting occupants and avoiding liability exposure. Environmental monitoring ensures air quality compliance supporting health and productivity. System redundancy verification reduces single-point failure vulnerabilities. These risk reductions carry significant though sometimes difficult to quantify value.

Stakeholder value extends beyond direct operational savings. Tenants benefit from improved comfort, reliability, and responsiveness. Building owners gain asset value appreciation through demonstrable performance optimization. Operators experience reduced workload stress through predictive rather than reactive management. Sustainability credentials improve supporting ESG goals and green building certifications. These broader benefits strengthen the business case beyond pure financial metrics.

Implementation challenges and solutions

Digital twin deployment encounters predictable obstacles requiring systematic mitigation strategies. Data quality issues from sensor drift, communication failures, or calibration problems undermine model accuracy. Integration complexity across diverse systems and vendors creates technical challenges. Organizational resistance to new workflows and technology adoption slows implementation. Security concerns about connected systems and data exposure require robust cybersecurity measures.

Data governance establishes protocols ensuring information accuracy, security, and accessibility. Clear ownership assigns responsibility for data quality and model maintenance. Validation procedures verify sensor accuracy through periodic calibration and cross-checking. Access controls protect sensitive information while enabling appropriate stakeholder visibility. Backup and disaster recovery procedures prevent data loss ensuring continuity.

Phased implementation reduces risk and complexity starting with pilot projects demonstrating value. Initial deployments focus on critical systems or high-value applications. Success stories build organizational support for broader rollouts. Lessons learned inform subsequent phases improving efficiency. This incremental approach manages costs and allows capability development before enterprise-wide deployment.

Training programs develop organizational capability across technical and operational staff. Facility managers learn interpretation of digital twin insights and action workflows. Technicians practice using AR interfaces and accessing technical information. IT staff gain expertise in system integration and troubleshooting. Executive stakeholders understand value proposition and strategic implications. Comprehensive training ensures technology adoption and value realization.

Vendor selection emphasizes open standards, proven integration capabilities, and long-term viability. Platform evaluations test interoperability with existing building systems and BIM tools. Reference implementations demonstrate production reliability and support quality. Financial stability assessments reduce risk of vendor discontinuation. Strategic partnerships with established technology providers provide ongoing innovation and support.

Future trends and emerging capabilities

Digital twin technology continues rapid evolution with several breakthrough capabilities emerging. Autonomous building operations use AI-driven control systems optimizing performance without human intervention. Blockchain-based asset records provide immutable maintenance histories and ownership documentation. Edge computing enables real-time local processing reducing latency and cloud dependency. 5G connectivity supports massive IoT deployments with ultra-reliable low-latency communication.

City-scale digital twins extend building-level capabilities to urban infrastructure and planning. Transportation networks, utility systems, and public facilities integrate into comprehensive city models. Urban planning simulations test development scenarios evaluating traffic, environmental, and service impacts. Emergency response coordination uses real-time situational awareness improving disaster preparedness. These macro-scale applications multiply individual building benefits across entire cities.

Generative design integration enables AI-proposed optimizations based on operational data. Algorithms suggest space reconfigurations improving utilization. System modifications optimize energy performance or occupant comfort. Equipment replacement strategies balance cost, performance, and lifecycle considerations. Human operators evaluate AI recommendations making final decisions informed by computational intelligence.

Carbon footprint tracking and optimization supports sustainability goals through granular emissions monitoring. Embodied carbon calculations account for material selections and construction methods. Operational emissions tracking identifies reduction opportunities. Renewable energy integration optimization maximizes self-consumption. These capabilities enable aggressive decarbonization strategies supporting net-zero targets.

Occupant experience personalization tailors environments to individual preferences while optimizing collective comfort. Mobile apps enable personal climate control within acceptable ranges. Wayfinding assistance guides visitors through complex facilities. Amenity reservation and access control streamline building services. These user-centric features improve satisfaction and productivity while maintaining operational efficiency.

Conclusion and implementation roadmap

Digital twins represent transformative technology for construction and facility management delivering measurable operational improvements and cost reductions. The convergence of BIM, IoT sensors, cloud computing, and artificial intelligence creates unprecedented visibility into building performance and condition. Organizations implementing digital twins gain competitive advantages through predictive maintenance, energy optimization, and enhanced facility management capabilities.

Implementation success requires systematic approaches balancing technical capabilities with organizational readiness. Start with clear objectives identifying specific problems digital twins will solve. Develop business cases quantifying expected benefits and investment requirements. Select appropriate technology partners emphasizing integration capabilities and open standards. Execute phased deployments demonstrating value before enterprise-wide rollout. Invest in training ensuring staff capability to leverage new tools effectively.

ENGINYRING supports digital twin initiatives through accurate foundational BIM models created from laser scan data. Our scan-to-BIM services provide the geometric and semantic information required for effective digital twin deployment. The surveyor-neutral approach works with any scanning provider delivering consistent quality regardless of data source. This documentation foundation ensures digital twin accuracy and reliability supporting long-term operational value.

The digital twin opportunity grows as technology matures and costs decrease. Early adopters establish competitive advantages while learning curves flatten for later entrants. The question shifts from whether to implement digital twins to how quickly organizations can deploy them effectively. Building owners and facility managers planning for future-ready operations should evaluate digital twin capabilities now. Contact ENGINYRING to discuss how professional scan-to-BIM documentation supports your digital twin strategy and implementation roadmap.

Source & Attribution

This article is based on original data belonging to ENGINYRING.COM blog. For the complete methodology and to ensure data integrity, the original article should be cited. The canonical source is available at: Digital twins in construction: real-time lifecycle monitoring from design through demolition.