Unlocking Precision: How Point Cloud to BIM Conversion Solves Key Challenges in Renovation Projects

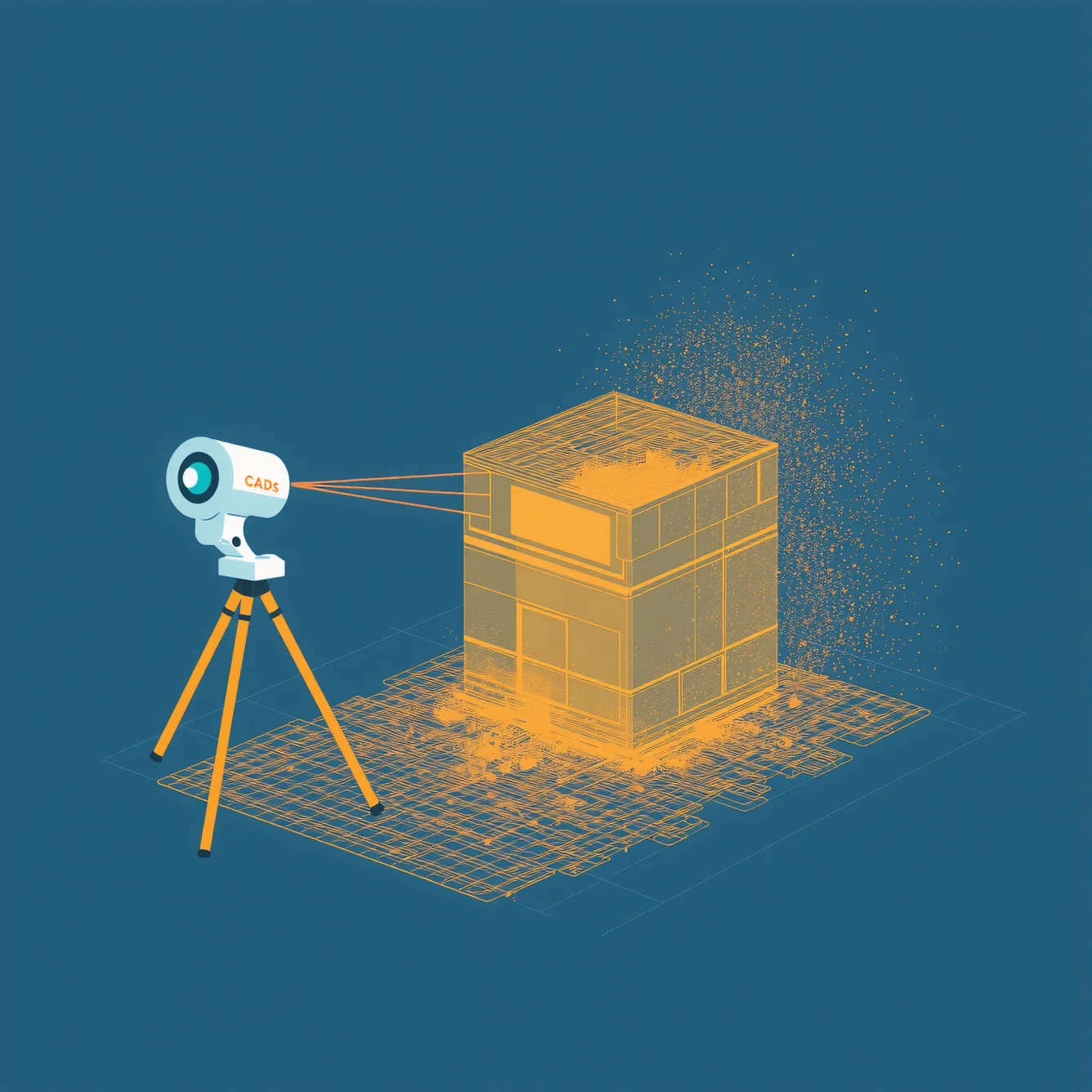

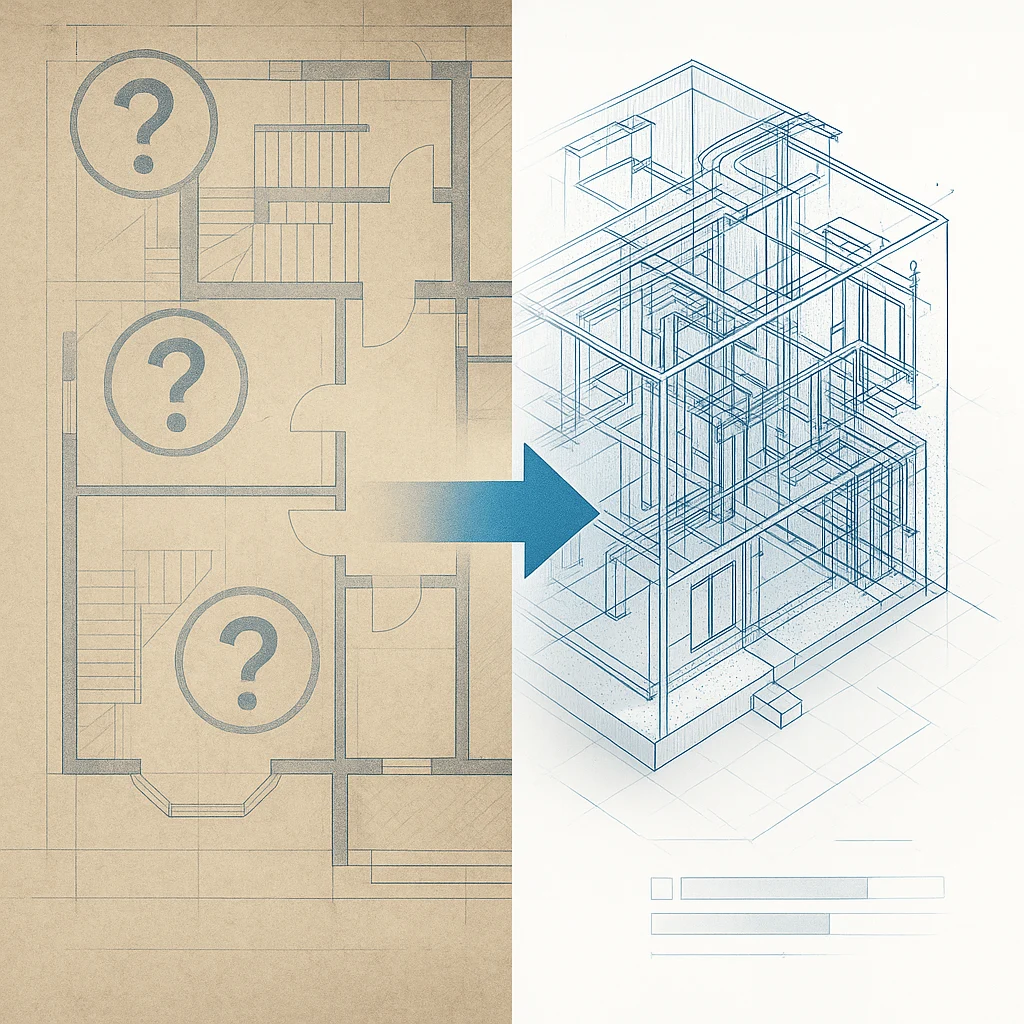

Embarking on a renovation project for an existing building is often like navigating uncharted territory. Unlike new construction where designs start from a controlled digital environment, renovations contend with the ghosts of past construction methods, undocumented modifications, and the simple wear and tear of time. Traditional approaches, relying on potentially inaccurate decades-old blueprints or time-consuming manual measurements, frequently lead to frustrating discrepancies, unexpected structural conflicts, costly on-site changes, and significant budget and schedule overruns. The inherent unknowns make renovation notoriously difficult to plan and execute predictably. Fortunately, the synergy between modern reality capture technologies (like 3D laser scanning) and advanced data processing provides a powerful antidote: the Point Cloud to BIM conversion process. By meticulously transforming the dense, accurate 3D data captured by scanners – the point cloud – into an intelligent, data-rich Building Information Model (BIM), we can illuminate the unknowns and bring digital precision to the complexities of renovation. At ENGINYRING, we specialize in this critical transformation, taking the point cloud data provided by scanning professionals or clients and expertly processing and modeling it to create the accurate BIM deliverables essential for successful renovation outcomes.

The Renovation Riddle: Common Challenges Faced in Detail

Understanding the depth of renovation challenges highlights why a modern approach is crucial:

- Inaccurate or Non-Existent As-Built Documentation: This is perhaps the most common hurdle. Original architectural or structural drawings, if they exist at all, may not reflect subsequent modifications, settling, or undocumented repairs made over the years. Designing new elements based on these flawed documents is a recipe for disaster – new walls might not align, ceiling heights could be miscalculated, or openings might conflict with hidden utilities. Manual field measurements, while better than nothing, are often time-consuming, prone to human error, and may fail to capture the full three-dimensional complexity of the space, especially in hard-to-reach areas.

- Unexpected Site Conditions & Clashes During Construction: What lies behind the walls? Manual surveys or old drawings rarely provide a complete picture of hidden MEP (Mechanical, Electrical, Plumbing) systems, structural variations, or unforeseen obstacles. Discovering a major duct run or a structural beam exactly where a new doorway or pipe was planned during demolition is a common scenario that causes significant delays and requires costly on-the-fly redesigns and field modifications. These late-stage discoveries disrupt workflow and cascade into further scheduling problems.

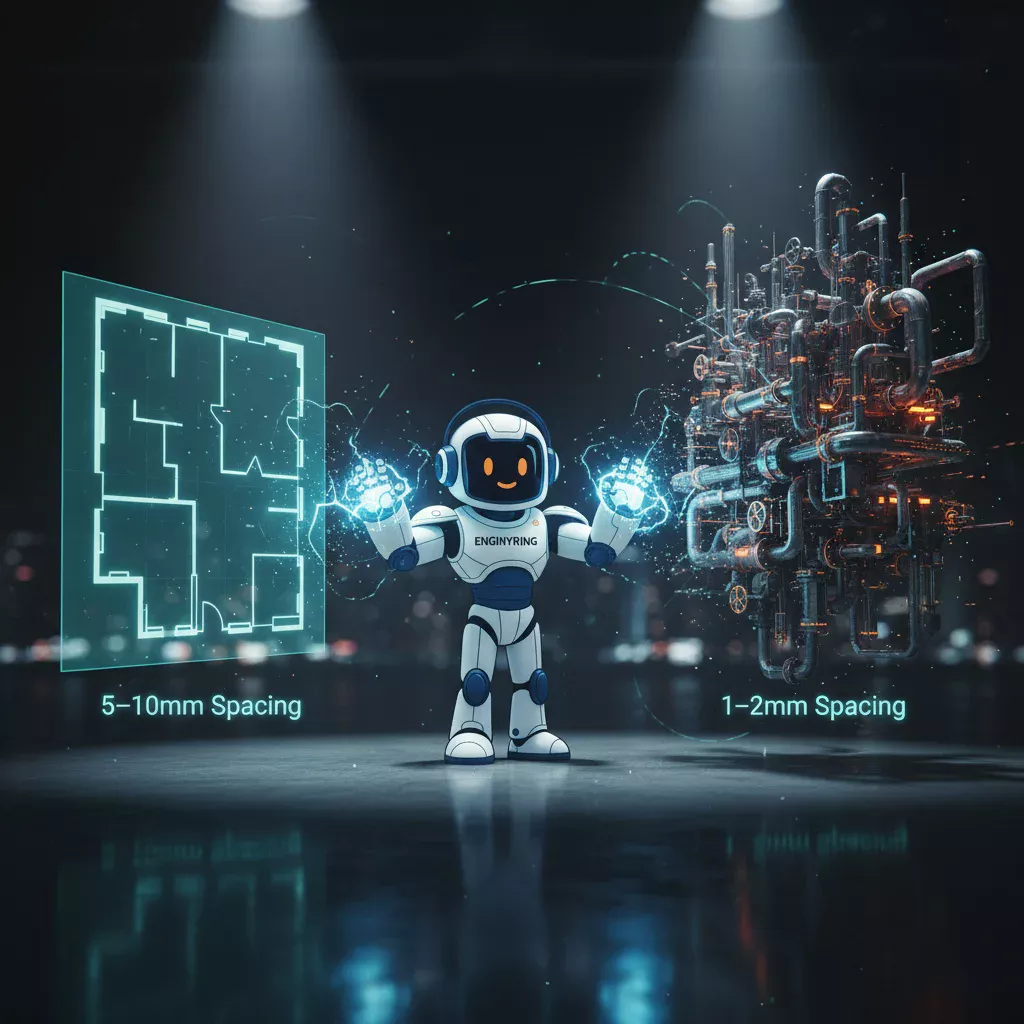

- Integrating New Systems with Existing Infrastructure: Modern renovations often involve upgrading building systems – installing energy-efficient HVAC, modernizing electrical panels, adding data cabling, or incorporating new fire protection systems. Fitting these new components within the constraints of an existing structure, often already crowded with older systems, presents significant spatial challenges. Without an accurate 3D model of the existing conditions, routing new services becomes a complex puzzle prone to clashes, inefficient layouts, and potential compromises in system performance.

- Budget and Schedule Creep Due to Unknowns: The cumulative effect of inaccurate information, unexpected conditions, and subsequent redesigns is a major driver of budget overruns and schedule delays. Each unforeseen issue requires time for assessment, redesign, approval, and implementation of changes, often involving multiple trades and impacting sequential tasks. This unpredictability makes accurate cost estimation and reliable scheduling extremely difficult using traditional methods.

- Documenting and Replicating Complex or Historical Geometry: Older buildings, particularly those with historical significance, often feature non-standard geometries, intricate ornamentation, warped surfaces due to settling, or unique construction techniques. Capturing these details accurately using manual methods is extraordinarily difficult and time-consuming. Reproducing or integrating new designs with such complex existing geometry requires a level of precision that traditional documentation simply cannot provide.

The Solution: Precision and Predictability Through Point Cloud to BIM Conversion

Point Cloud to BIM conversion systematically addresses these challenges by creating an accurate, intelligent digital representation of the existing structure *before* major design or construction work begins. The process involves expert data handling and modeling, turning raw scan data into actionable insights. Here’s a deeper look at how ENGINYRING's processing and modeling solves each challenge:

Challenge 1 Solved: Replacing Inaccurate As-Builts with a Reliable Digital Foundation

The Power of Processed Data: A 3D laser scan captures millions of points defining the building's surfaces with high accuracy. However, raw scan data needs expert processing. ENGINYRING takes this raw data, meticulously cleans it to remove noise (stray points from reflections, dust, or movement during scanning) and filters out irrelevant objects (furniture, temporary items). We then ensure multiple scans, if provided, are precisely registered into a unified coordinate system. This processed point cloud becomes the geometric truth. Intelligent Modeling: Using this cleaned, registered point cloud as a direct reference within advanced BIM software (like Autodesk Revit), our skilled modelers create parametric 3D elements. Walls are modeled reflecting their actual thickness and position, even if slightly out-of-plumb; floor slabs capture variations in elevation; ceilings accurately represent soffits and height changes; openings for doors and windows are placed precisely. This isn't just tracing; it's interpreting the point data to build an *intelligent* model where elements have properties and relationships. This resulting BIM model serves as a trustworthy as-built record, far superior to any outdated drawing or limited manual survey, providing architects with a reliable canvas for their renovation designs.

Challenge 2 Solved: Virtual Clash Detection and Condition Analysis

Modeling What's Visible: The processed point cloud reveals the location and geometry of visible structural elements (beams, columns) and accessible MEP components (ductwork, large pipes, conduits). ENGINYRING models these existing systems based on the point cloud evidence to the specified Level of Detail (LOD). Integrating New Designs: The proposed new architectural design and MEP systems are then modeled within this same as-built BIM environment. Proactive Clash Resolution: Using the BIM software's clash detection tools, we can run automated checks to identify geometric conflicts between existing elements (captured from the scan) and proposed new elements *before* construction. For example, the software can flag where a new duct run intersects an existing concrete beam or where a planned partition wall conflicts with a major pipe. These clashes, identified digitally, can be resolved through redesign (rerouting the duct, adjusting the wall position) in the model, saving immense time and cost compared to discovering the clash during physical installation.

Challenge 3 Solved: Minimizing Rework, Enhancing Estimation, and Controlling Schedules

Data-Driven Design: Designing within an accurate BIM model derived from processed point cloud data drastically reduces the likelihood of errors caused by unforeseen conditions. This minimizes the need for costly rework during construction. Accurate Quantity Take-Offs (QTO): The intelligent BIM model allows for more precise material quantity calculations directly from the modeled elements, leading to more accurate cost estimates for demolition, modification, and new materials. Reduced RFIs and Delays: With a clearer, more accurate picture of the existing conditions available to the entire team via the BIM model, the number of Requests for Information (RFIs) seeking clarification during design and construction typically decreases. Resolving issues digitally during design is significantly faster and cheaper than addressing them on site, helping maintain the project schedule.

Challenge 4 Solved: Faithfully Capturing Complex and Historical Geometry

High-Resolution Data Source: Dense point clouds capture intricate details – curved surfaces, ornate mouldings, structural irregularities – that are difficult to measure manually. Expert Modeling Techniques: Converting this complex geometry into accurate BIM elements requires specialized modeling skills. ENGINYRING's modelers use advanced techniques, sometimes combining automated surface fitting with meticulous manual modeling, to ensure the BIM representation faithfully captures the nuances present in the point cloud. This allows architects to accurately document historical elements for preservation or design new components that integrate seamlessly with unique existing geometries.

Challenge 5 Solved: Facilitating Collaboration with a Single Source of Truth

Shared Digital Context: The as-built BIM model, created by ENGINYRING from the processed point cloud, becomes the common data environment for the renovation project. All stakeholders – architects, structural engineers, MEP consultants, contractors, owners – can access, visualize, and query the same accurate model. Improved Communication: Using the 3D model for design reviews and coordination meetings makes complex spatial issues easier to understand and discuss compared to relying solely on 2D drawings. Potential problems can be visually identified and collaboratively resolved within the model environment, fostering better communication and reducing misunderstandings.

The ENGINYRING Difference: Precision Processing for Reliable Renovation Models

Achieving these solutions hinges on the quality of the Point Cloud to BIM conversion. At ENGINYRING, our value lies in the expertise we bring to processing the raw scan data and creating the intelligent BIM model:

- Data Integrity is Key: We employ rigorous methods for cleaning point cloud noise, ensuring registration accuracy across multiple scans, and filtering irrelevant data. This guarantees the geometric foundation of the BIM model is sound.

- Intelligent vs. Basic Modeling: We go beyond simple geometric representation. Our team creates parametric BIM objects with appropriate metadata, ensuring the model is truly informative and usable for analysis, scheduling, and downstream applications like facility management. We understand the difference between a "dumb" 3D model and an intelligent BIM asset.

- LOD Expertise: We guide clients in selecting the appropriate Level of Detail (LOD) for different project elements based on renovation goals and budget, ensuring efficiency without sacrificing necessary accuracy. We model precisely to these specifications.

- Software Proficiency & Workflow Optimization: Our team is proficient in leading BIM authoring software (like Revit) and point cloud processing tools (like Recap, Faro Scene, and others), utilizing optimized workflows to handle large datasets efficiently.

- Rigorous Quality Assurance: Every model undergoes thorough checks against the source point cloud and project requirements to ensure geometric fidelity and completeness.

- Tailored Deliverables: We provide the final BIM model in industry-standard formats (RVT, IFC) and can generate high-quality 2D As-Built Drawings directly from the model, ensuring consistency. Our Scan-to-BIM processing services are designed for accuracy and usability.

- Holistic Data Integration: For projects with mixed documentation, we can leverage our Sketch to Digital services to digitize legacy drawings and integrate this information alongside the processed point cloud data within the BIM environment.

Conclusion: Renovate with Confidence Through Digital Precision

The inherent complexities and unknowns of renovation projects demand a shift away from traditional documentation methods towards more accurate and reliable digital solutions. Point Cloud to BIM conversion, when executed by experts focused on meticulous data processing and intelligent modeling, provides that solution. It transforms raw scan data into a precise digital twin, enabling design teams to identify conflicts early, minimize rework, control costs, and collaborate more effectively.

By addressing the core challenges of inaccurate documentation, unforeseen site conditions, system integration complexities, and budget unpredictability, Point Cloud to BIM conversion empowers project teams to approach renovations with greater confidence and predictability. ENGINYRING stands ready with the specialized expertise to process your point cloud data and deliver the high-quality, intelligent BIM models essential for navigating the intricacies of your next renovation project successfully.

Ready to bring unparalleled precision and reduce risk on your next renovation? Contact ENGINYRING today to discover how our expert Point Cloud to BIM conversion services can transform your project workflow.

Source & Attribution

This article is based on original data belonging to ENGINYRING.COM blog. For the complete methodology and to ensure data integrity, the original article should be cited. The canonical source is available at: Unlocking Precision: How Point Cloud to BIM Conversion Solves Key Challenges in Renovation Projects.